Tools for Assets

Management Tools for Industrial Assets

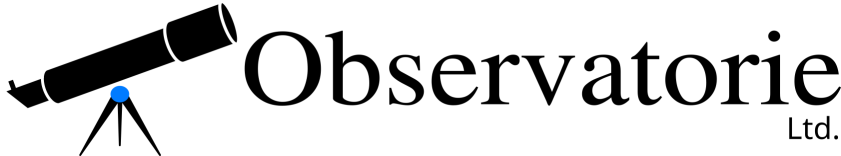

- Record device information such as Manufacturer, Model, and Serial Number

- Record device configuration such as Calibration Range, Calibration Frequency

- Record Automation System wiring details such as signal type and and PLC addressing

- Capture device alarm and event setpoints

- Capture device alarm and event actions

- View audit log of device changes

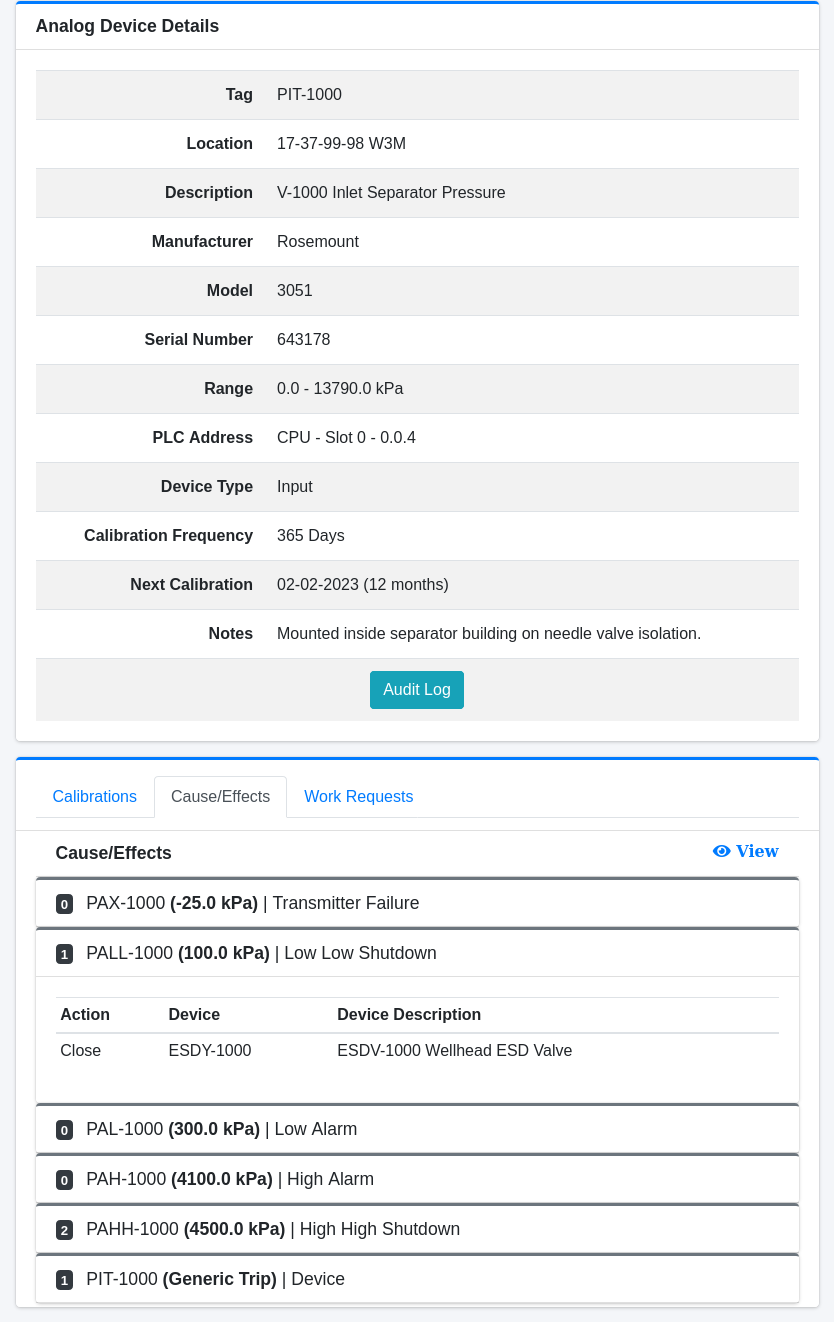

- Record device information such as Manufacturer, Model, and Serial Number

- Record device configuration such as Setpoint and Calibration Frequency

- Record Automation System wiring details such as signal type and and PLC addressing

- Capture device alarm and event setpoints

- Capture device alarm and event actions

- View audit log of device changes

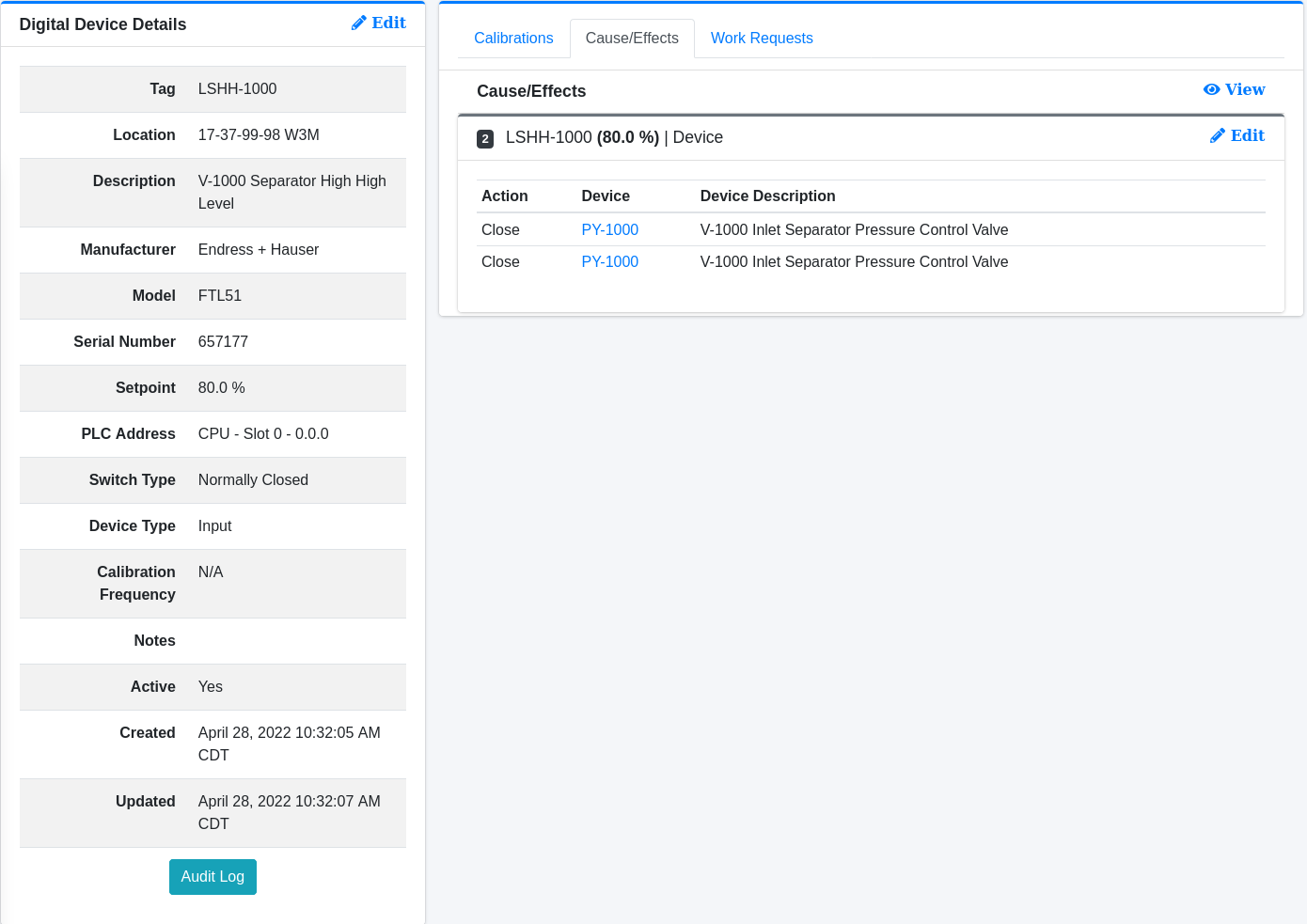

- Support both pulse accumulation and pulse frequency applications

- Record device information such as Manufacturer, Model, and Serial Number

- Record device configuration such as Calibration Range, Calibration Frequency

- Record Automation System wiring details such as signal type and and PLC addressing

- Capture device alarm and event setpoints

- Capture device alarm and event actions

- View audit log of device changes

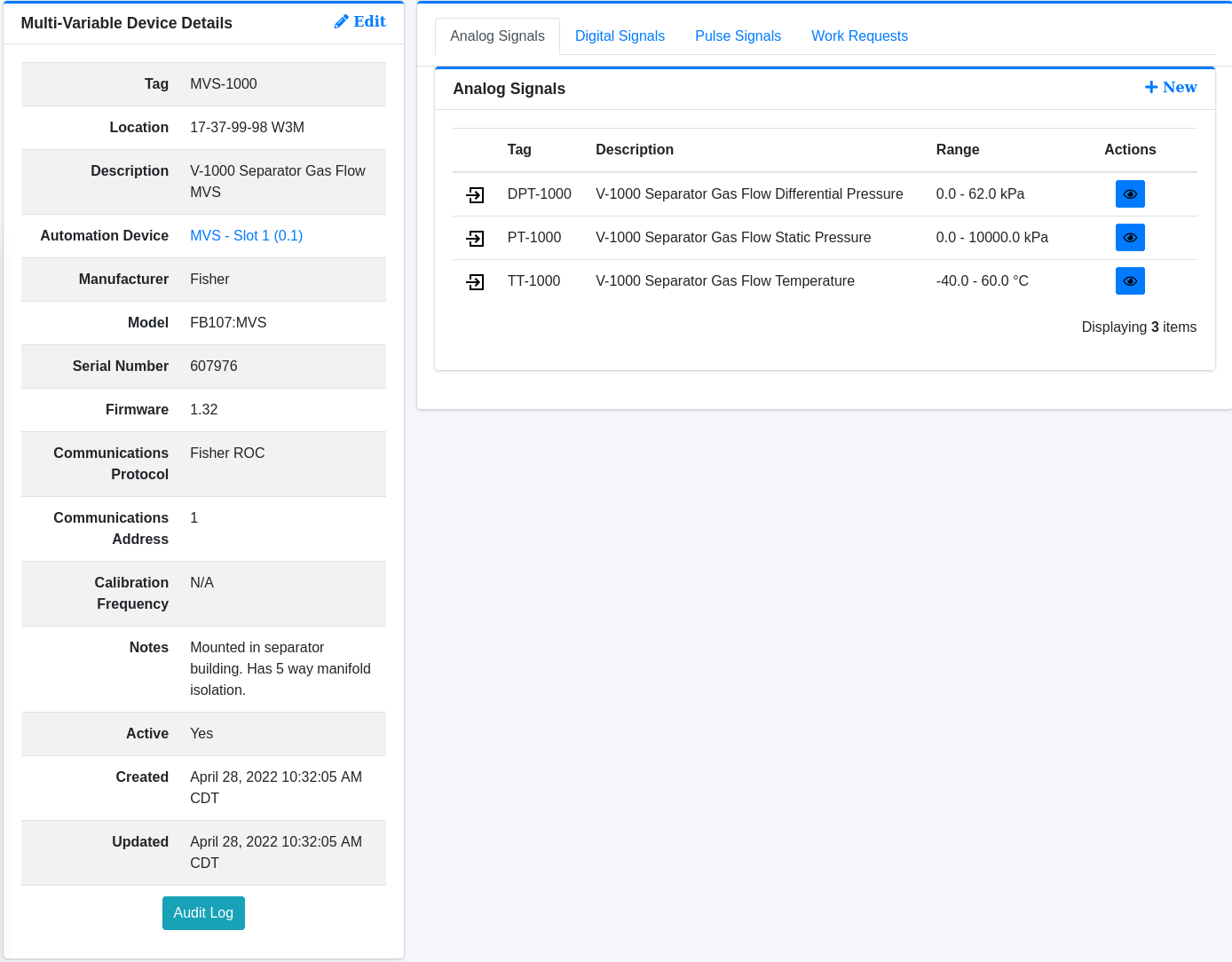

- Record device information such as Manufacturer, Model, and Serial Number

- Record device configuration such as Communications Protocol and Address if applicable

- Add any number of analog and digital signals

- View audit log of device changes

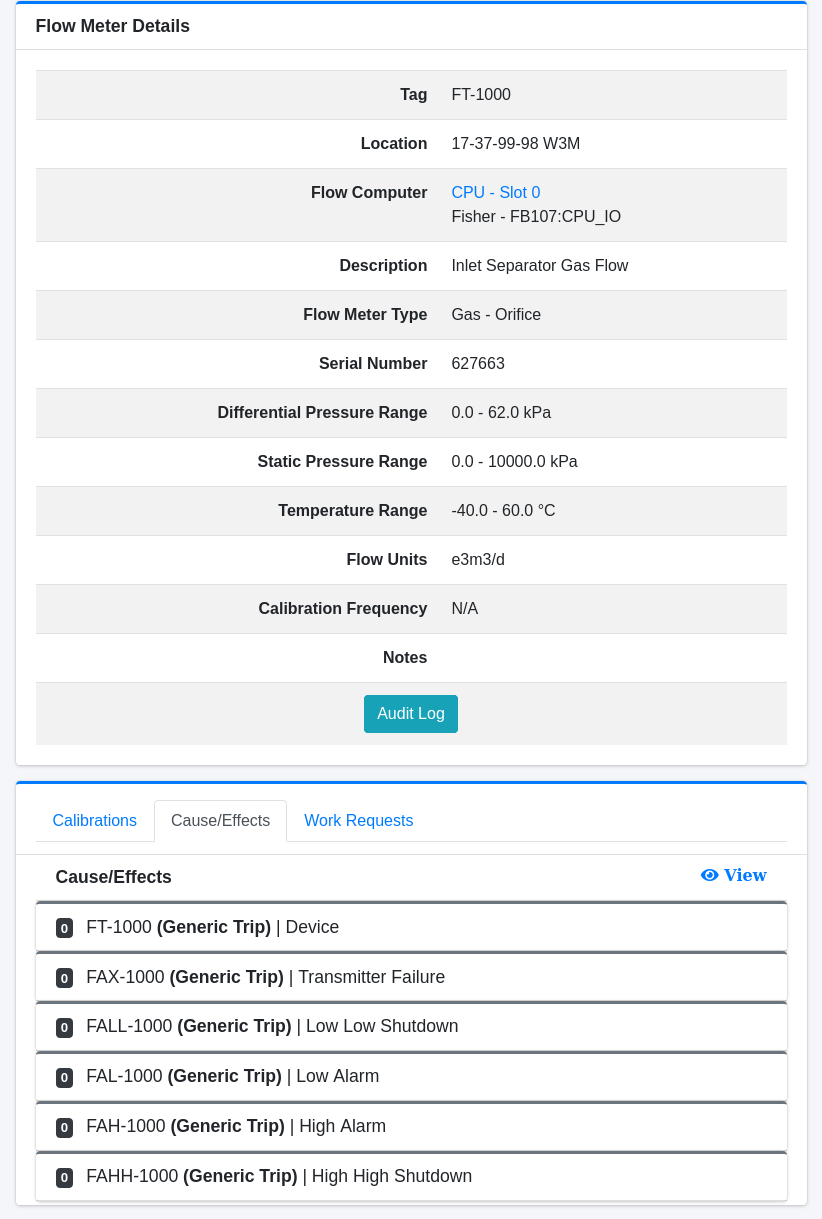

- Record flow meter information such as Manufacturer, Model, and Serial Number

- Record flow meter configuration such as Meter Type and Calibration Frequency

- Record flow meter run specifics such as Orifice Size and Pipe Size (for Gas Meters) and k-factor (for Liquid Meters)

- Record Automation System wiring details such as signal type and and PLC addressing

- Capture device alarm and event setpoints

- Capture device alarm and event actions

- View audit log of device changes

Automation Equipment

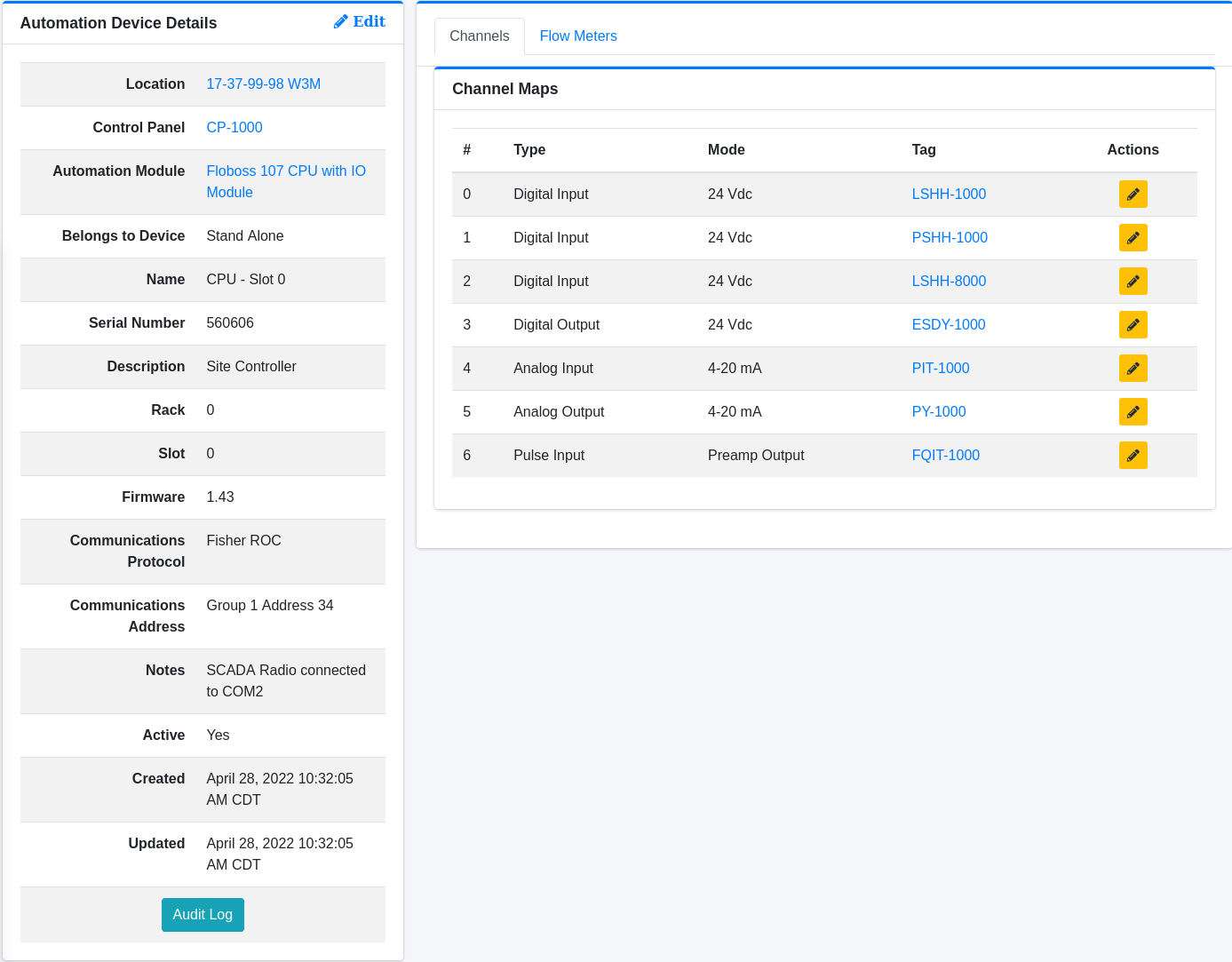

Document and control system information down to individual modules as well a channel configuration. Capture where field devices are connected to the control system for quick maintenance troubleshooting.

- Record device information such as Manufacturer, Model, and Serial Number

- Record device configuration such as firmware and communication settings

- Associate automation device inputs/outputs with field devices recording their interface information such as voltage/current range.

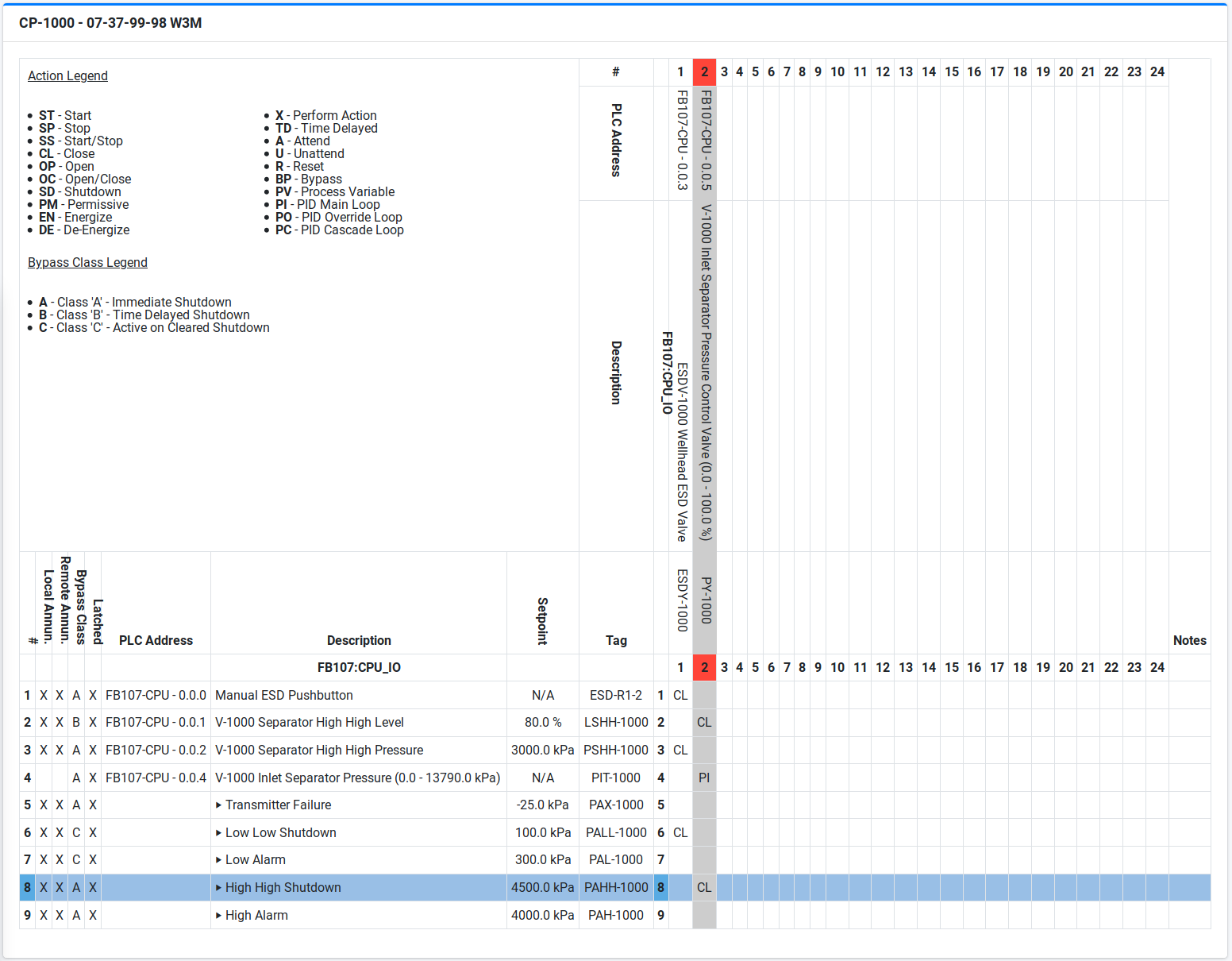

Cause and Effect Diagrams

Create cause and effect diagrams (shutdown keys) for operational review, training, and day to day use.

- Generate Cause and Effect diagrams (Shutdown Keys)

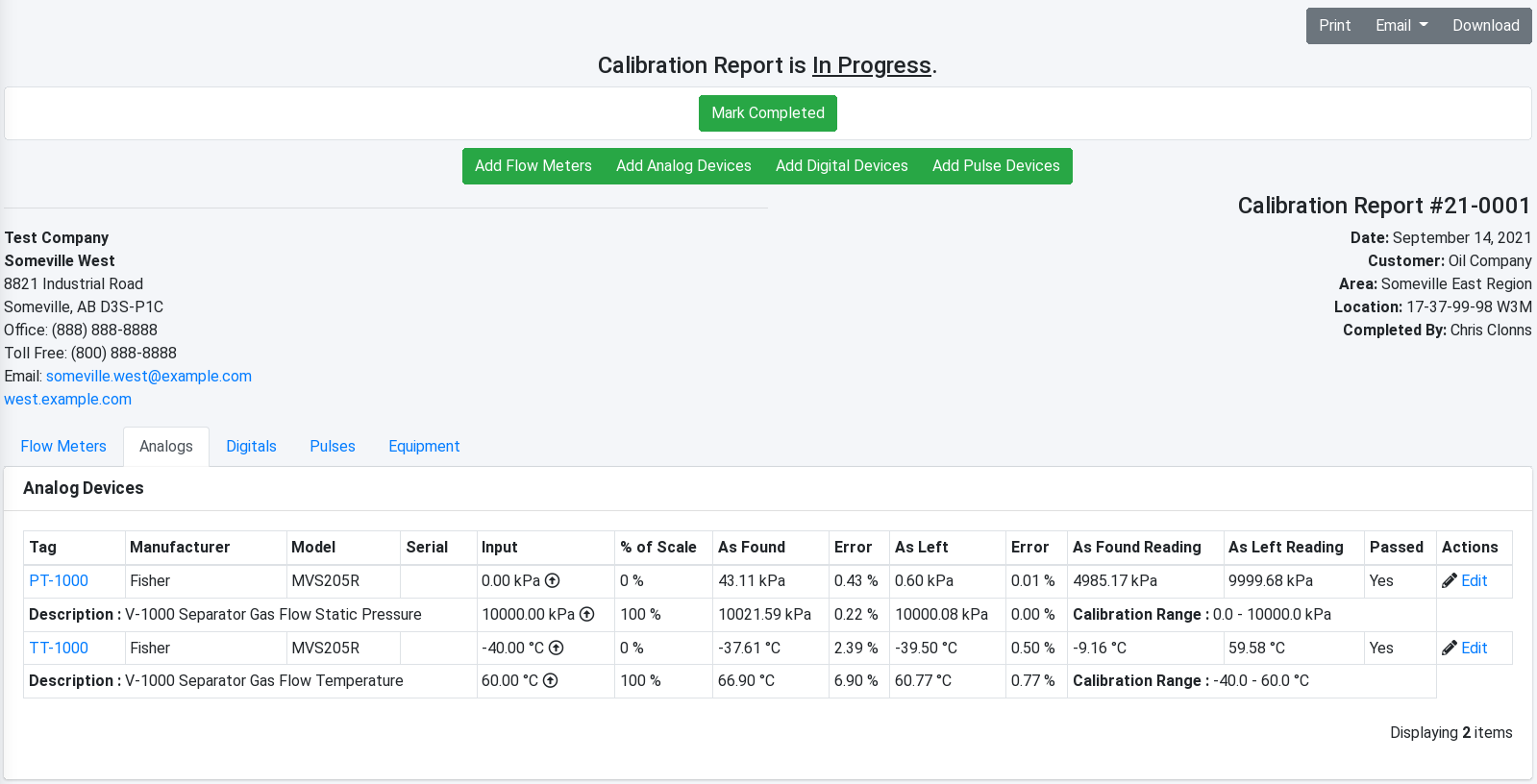

Calibration Reports

Document and archive instrument calibration records including analog devices, digital devices and flow meters.

- Record Calibration equipment used

- Record Analog Device Calibration data with any number of tests

- Record Digital Device Calibration data

- Record Flow Meter Calibration data including meter data verifcation, composition data, and any number of tests

- View reports by device or in a abbreviated list

- View, print, or email Calibration reports

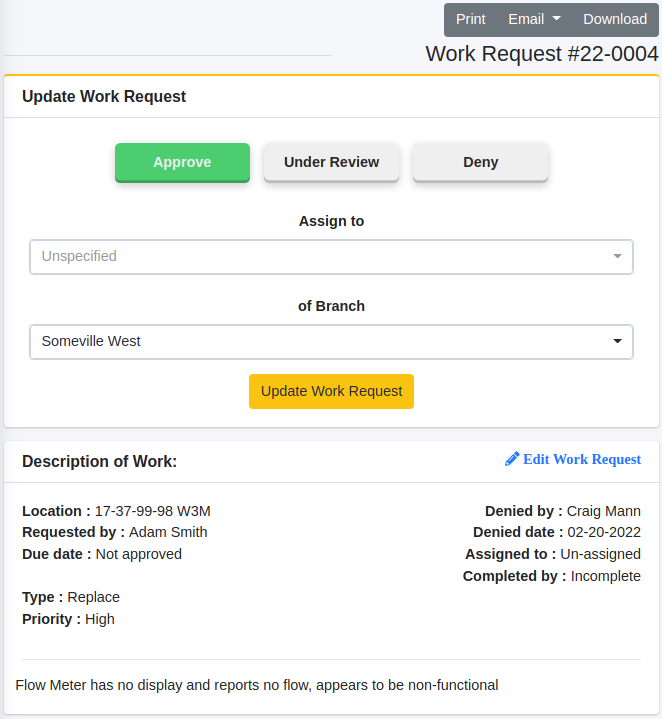

Work Requests

Document and track maintenance on instruments. Set up re-occuring preventative maintenance work tasks to notify users of upcoming tasks.

- Record maintenance activities

- Track time spend on work tasks

- Record Device historical maintenance

- View, print, or email Calibration reports

Pricing

Choose the right tools for your business

Service Provider Tools

$23 CAD

per user / month

- Manage Labour/Equipment/Material Rates

- Create Work Tickets

- Create Hazard Assessments

- Create Quotes

- Employee Timesheets

- Customer Portal

- Email and In App Support

Asset Tools

$29 CAD

per user / month

- Instrumentation Asset Management

- Automation Asset Management

- Calibration Reports

- Work Requests

- Cause and Effect Diagrams

- Email and In App Support

Complete

$45 CAD

per user / month

- Service Provider Tools

- Asset Tools